Solution Suggestions

How to Choose the Right Insulation Material?

12.09.2025

The key to energy savings in buildings is reducing heat loss. The right insulation material, applied correctly—from walls to roofs, floors to foundations and retaining walls—increases comfort and permanently lowers heating and cooling costs.

Golden Criteria for Selecting Insulation Materials

- Climate / Thermal Zone: The building’s thermal zone and elevation determine the required insulation thickness (TS 825 approach).

- Target U-Value: Define the target U-value (W/m²K) for walls, roofs, and floors; material thermal conductivity (λ), thickness, and detailing are selected accordingly.

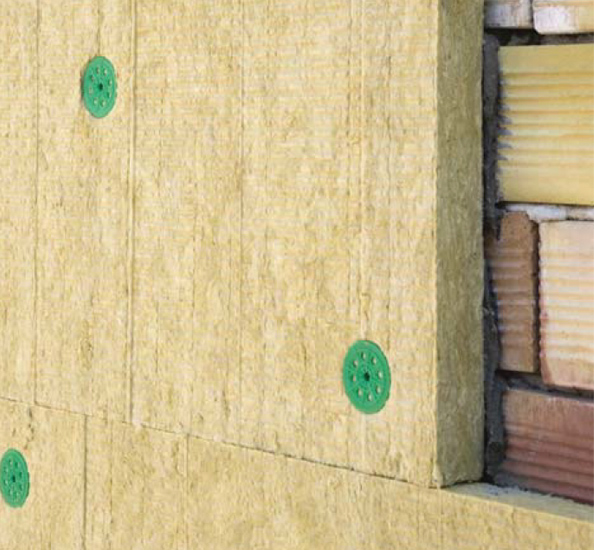

- Building Composition & Details: Structural walls, cladding, number of anchors, window/floor junctions, and thermal bridges must all be considered.

- Moisture & Water Management: Plan for vapor diffusion, water absorption, and drainage in exterior walls, roofs, and areas in contact with the ground such as foundations and retaining walls.

- Mechanical Strength: Compressive strength, impact, and wind resistance (ETICS anchoring/mesh reinforcement) determine the application lifespan.

- Fire & Environment: Fire classification, UV resistance (final coat), and recyclability should be considered in system selection.

Why Choose Epsa Materials?

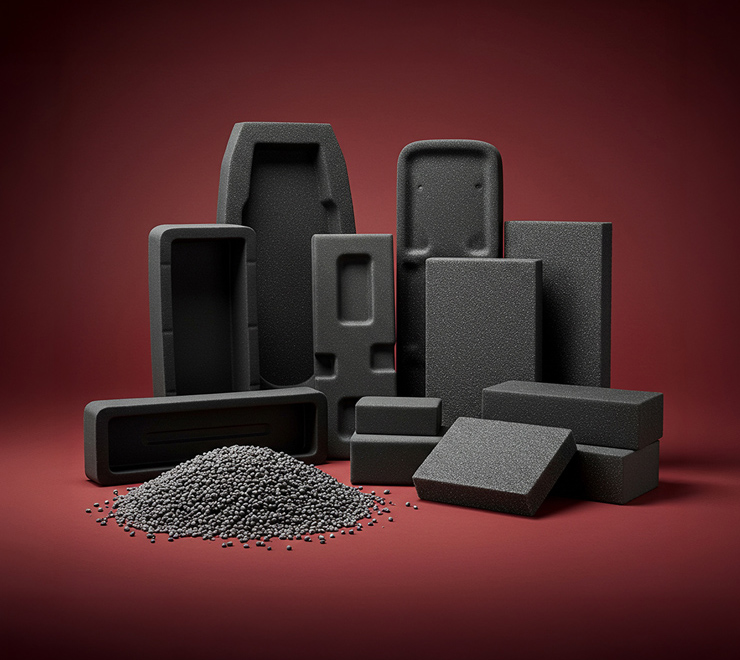

Epsa provides end-to-end support for insulation projects; from site surveys to thermal bridge analysis, from thickness calculations to system selection and installation training, every step is carefully managed. EPS insulation offers high thermal resistance with low λ values thanks to its lightweight and efficient structure, allowing easy installation on façades, roofs, and floors. Its products are economical and accessible, with a wide range of densities and thicknesses optimizing cost-performance balance. Epsa materials provide long-lasting, system-compatible solutions in ETICS (external thermal insulation composite systems) through proper adhesion, anchoring, plaster/mesh application, and finishing coat. Correct layering ensures long-term performance on façades, roofs, floors, foundations, and retaining walls, while flexibility in detailing allows easy adaptation to different project requirements, such as under-floor areas, foundations, and roof interlayers. Lightweight and fast-applicable materials combine speed and quality on-site, with checklists and site inspections ensuring sustainable quality. Planned production and delivery guarantee logistics and scheduling reliability, supporting timely project completion.

EPS Solutions by Application Area

- Exterior Façade (ETICS / Insulation Systems): EPS boards applied with adhesive and anchors, combined with fiberglass mesh-reinforced plaster, primer, and finishing coats, provide low U-value, crack control, and long lifespan. Protects your home’s exterior both aesthetically and energy-efficiently.

- Roof & Ceiling: EPS used under screed or in roof interlayers offers lightweight and fast application for easy installation. It also enhances thermal comfort and ensures protection in water-exposed areas of inverted roofs through system detailing.

- Underfloor: EPS installed under screed provides both thermal and acoustic comfort. When combined with waterproofing details in wet areas or ground-contact zones, it delivers long-lasting and secure solutions.

- Foundations & Retaining Walls: EPS in ground-contact areas is planned with thermal insulation, waterproofing, and drainage boards. Supported with geotextile or protective panels for mechanical protection, it enhances the strength and comfort of your building.